Mixing pumps

Combined mixing and pumping for the processing of mortar, screed and refractory materials

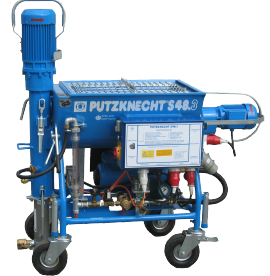

Putzknecht S48.3 / S48easy

Our all-time favourite – continuously developed based on decades of experience on thousands of construction sites. Our S48 models – whether in the basic S48easy or the S48.3 comfort version – combine robust, easy-to-clean technology with powerful performance, providing you with a unit that will serve you faithfully for decades.

Thanks to the narrow design with a width of only 80 centimetres, our S48 easily fits through any door.

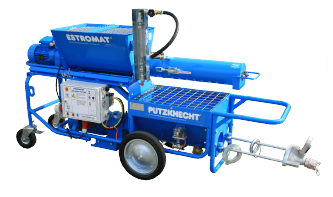

Putzknecht S44

Frequently copied, but never really equalled – this is our small mixing pump with the big benefits. Can be disassembled in a few easy steps to easily fit into any van. Available as 400V and 230V versions or switchable to 230V/400V operation.

Extensive, optional accessories such as blow-in and transfer bonnets, add-on containers, anti-dust bonnets, etc. make “tiny” an all-rounder

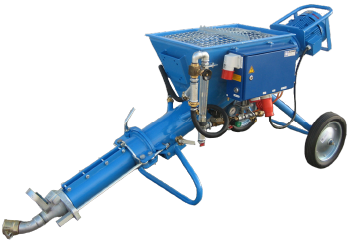

Putzknecht S36

Our specialist for processing materials with variable or long mixing times. The unit will mix as long as no material is being conveyed. The pump mode is activated via cable or radio remote control (optional). If no more material is conveyed, the machine automatically switches to mixing mode. The speed and hence also the flow rate are infinitely adjustable.

Optimally suited for frame mortar, fire retardant mortar, grouting mortar, etc. Optional accessories such as frame backfilling gun, glue spray gun etc. are available.

Developed for highly demanding and abrasive materials, our S36 is also appealing from a financial point of view thanks to its extremely robust design with minimal maintenance requirements and a long service life of components subject to wear!

Putzknecht S30-TM 100

Compact, powerful mortar pump with built-on TM 100 pan mixer. The design of the mortar pump allows using another, separate pan mixer. The larger material hopper allows for quick and comfortable handling, even with large conveyor volumes.

The continuously adjustable drive allows the conveyor rate to be optimally adjusted to your needs.

Available with 5.5kW or 7.5kW drive. The machine can also be fitted with optional gunning equipment, a vibrating sieve and remote control.

Putzknecht S30-E404

Powerful mortar pump with continuously adjustable speed and fixed flow mixer. The continuous mixer can be shifted on the machine frame and thus combines the benefits of a compact, combo design with the optimum accessibility for cleaning purposes offered by an open system.

A sophisticated, robust water metering system ensures consistent material quality.

Available in different performance versions and designs – contact us!

Putzknecht S58

Developed for heavy duty slurry gunning mixes for refractory applications, our S58 enjoys great popularity, also among plastering professionals. This is an extremely robust machine that is capable of mastering even the most demanding applications at all times. Just like our S48, the machine can be optimally adjusted to your applications due to a wide range of optional accessories such as injection bonnets, anti-dust bonnets, various mixing tools, etc.

The picture shows a special application with big bag loading. Plenty of manufacturers offer off-the-shelf solutions – we are your go-to partner for demanding applications!

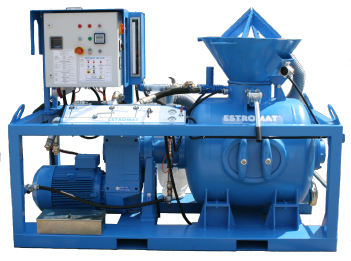

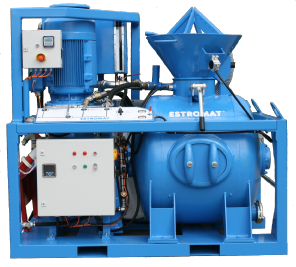

Estromat S70

Originally developed for processing flowing screeds, even we sometimes can’t believe all the applications our customers are using the S70 for…

Are you looking for a machine that allows you to process large volumes from a silo but also to work with bagged material at small-scale construction sites and even process filler material? Then Estromat S70 is the right solution for you.

With a mixing and pumping capacity of up to 120 litres/minute, this machine is also used in highly specialised applications such as canal and tunnel construction.

Putzknecht S82

Hydraulic diesel plastering machine with hydraulic mixer and integrated compressor.

The material is mixed in the mixer fitted on the side and then hydraulically emptied into the pump container. The next batch can already be prepared while the mixed material is being applied. Also ideal for mixtures of pumpable materials at construction sites.

Despite these performance features, our S82 has a maximum weight of only 750 kg and can therefore also be towed by small vehicles.

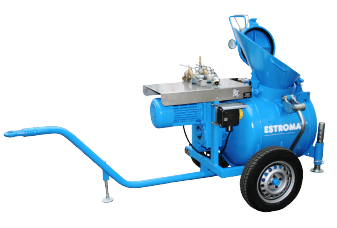

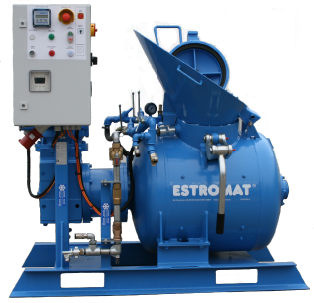

Estromat 260

The small, manageable, cost-effective alternative for the application of cementitious and anhydrite screeds.

The 260-litre mixing vessel is powered by a 7.5kW electric motor. Due to the special design of the mixing vessel, which was originally developed for refractory materials, optimum mixing results are achieved, even with a short mixing time. The required conveyor air is supplied by an external compressor (not included in the scope of delivery).

The machine is available with and without road clearance.

Estromat 264

Our smallest pressure mixer with a great performance!

Our units for the processing refractory mixes are not modifications of standard machines, but were specially developed for heavy-duty use in steelworks and foundries!

Equipped with an 11 kW drive, it is designed for demanding applications in the processing of refractory materials. Thanks to its special design, the 260-litre vessel produces the best mixing results even with difficult materials and short mixing times. Thanks to the built-in batch controller, the addition of water and other liquid additives is finely dosed and done automatically.

Our E264 is available with a wide range of equipment options and can thus be optimally adjusted to your requirements – contact us!

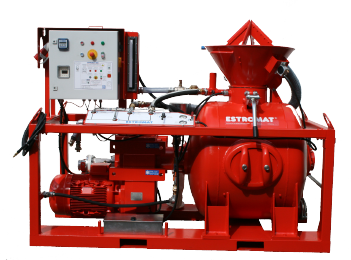

Estromat 426

The tried and tested machine for the professional processing of slurry gunning mixes.

All over the world, steel mills, foundries, furnace construction companies and material manufacturers rely on our expertise, which has been channelled into the design of our E426 and spurs us on in our continuous improvement of the unit. Estromat E426 is used around the clock, in all climate zones, and on all continents (with the exception of Antarctica)!

By default, the machine offers a storage silo with a useful capacity of 2.3m³ and a pump capacity of up to 80 l/min. But standard applications are the exception with our customers, which is why our E426 can do so much more!

Feed silos for very large volumes, interfaces for injection manipulators and robots (the machine can also still be operated manually), water heating or cooling, connection to process control benches, digital archiving of mixing and pumping parameters, combined systems for processing two or more different materials on one line – the variety of special designs already realised is almost endless.

But what sets our unit apart? The answer is: It is designed to be as simple as possible and as complicated as necessary!

Estromat E426 is designed to be your dependable, uncomplicated companion, a partner that solves problems without causing any!

Others tried to copy the Estromat E426, but the practical benefit often lies in the details. The original offers you numerous benefits, including a service life of the mixing and pumping components that is unique in the market and has never been achieved by the “copycats”! Because we understand why a component needs to look the way it does…

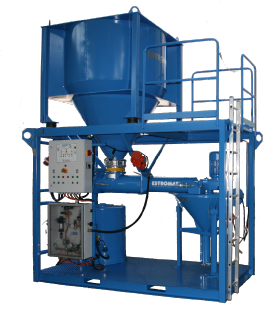

Estromat E260-600

Are you looking for a machine that is able to fill (small) big bags and, if necessary, also bagged materials, without compromising on performance and ease of use? Then our Estromat E260-600 is the right solution for you!

Our units for the processing refractory mixes are not modifications of standard machines, but were specially developed for heavy-duty use in steelworks and foundries!

The chamber has a usable capacity of 600 litres is designed in such a way that it can be filled with small big bags or bagged goods. With a drive power of 30 kW, processing heavy refractory mixes is a breeze. The water tank included in the standard scope of delivery, which regulates the supply of the mixing water or the supply of liquid additives via a finely dosed batch controller, ensures absolutely consistent material quality and short processing times.

With a large number of equipment features and optional accessories such as dispensers, dust extractors, etc., the machine becomes a customised problem solver.

Benefit from our more than five decades of experience in the manufacture of machinery for the processing of refractory materials!

T112

Our small machine for the processing of dry gunning mixes and shotcrete. With a gunning capacity of 0.5–4 m³ per hour and a maximum grain size of 20 mm, the machine provides powerful performance in a compact and handy design. The low-wear rotor output features a service-friendly design, requiring little maintenance, which can be carried out effortlessly and without being too time-consuming.

Our machine can be optimally adjusted to your requirements thanks to a wide range of equipment options – contact us!

T115

Our tried and tested solution for conveying and processing dry gunning masses, but also dusty media or granules in the pneumatic thin-flow conveying process. By default, our T115s are equipped with pressure vessels with a useful capacity of 1,100 litres – larger volumes are of course possible.

The machine can be optionally equipped with a purely pneumatic outlet or with an extremely low-wear rotor outlet for fine-tuning the conveyor flow. The basic model can be equipped with a wide range of optional accessories such as various feed silos, automated feeding systems, gunning and output packages, diesel-powered or electric, remote-controlled gunning manipulators, etc.

Especially when used in pneumatic thin-flow conveyor systems, the T115 often forms part of a large overall system. Not a problem for us – you define the interfaces and we design the integration into your system together with you.

Estromat E850

This is our largest pressure vessel mixing machine with a useful capacity of 850 litres. The vessel size is designed for processing whole big bags.

Our units for the processing refractory mixes are not modifications of standard machines, but were specially developed for heavy-duty use in steelworks and foundries!

With a drive power of 30 kW, processing heavy refractory mixes is a breeze. The water tank included in the standard scope of delivery, which regulates the supply of the mixing water or the supply of liquid additives via a finely dosed batch controller, ensures absolutely consistent material quality and short processing times. Optional accessories such as a swivelling boom or a wide variety of outlets ensure maximum user-friendliness, even after the mixing and pumping process.

We have five decades of experience in the manufacture of refractory machines and can design the optimum solution for your application from a wide range of options – contact us!

Estromat E850 short version

Specially developed for companies that often have to transport their equipment over longer distances, our “short” E850′ offers the advantage of a compact size. With an overall length of only 2,180mm, the machine fits on any truck!

Needless to say that you don’t have to compromise on performance or handling in any way.

With a usable capacity of 850 litres, the machine is designed for processing entire big bags.

Our units for the processing refractory mixes are not modifications of standard machines, but were specially developed for heavy-duty use in steelworks and foundries!

With a drive power of 30 kW, processing heavy refractory mixes is a breeze. The water tank included in the standard scope of delivery, which regulates the supply of the mixing water or the supply of liquid additives via a finely dosed batch controller, ensures absolutely consistent material quality and short processing times. Optional accessories such as a swivelling boom or a wide variety of outlets ensure maximum user-friendliness, even after the mixing and pumping process.

We have five decades of experience in the manufacture of refractory machines and can design the optimum solution for your application from a wide range of options – contact us!