Refractory applications

Machines for processing unbound, refractory materials, casting compounds, gunning mixes, etc.

Machines for processing unbound, refractory materials, casting compounds, gunning mixes…

Our Estromat range is specifically designed for mixing and pumping materials exposed to very high temperatures and/or molten metals.

All over the world, our customers trust in the reliability and durability of our machines Made in Germany.

Around the clock – on all continents (with the exception of Antarctica)

PROCESSING OF SLURRIES

Mixing pumps

Putzknecht S58

Our “tiny” unit for the processing of heavy slurries. By default, the machine is fed with bagged material and is thus ideally suited for smaller applications in the refractory sector. But even if larger volumes of material are to be processed, our S58 has a lot to offer – the picture shows special equipment for big bag loading (two big bags fit into the storage container).

The scope of delivery includes a complete set of spraying equipment.

A wide range of optional accessories is available for this machine to suit a wide variety of applications – all of course in the renowned Uelzener Quality Made in Germany!

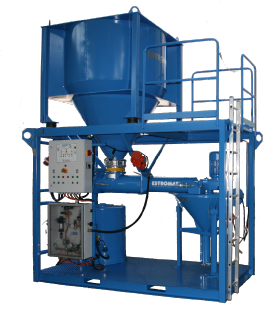

Estromat 426

The tried and tested machine for the professional processing of slurry gunning mixes.

All over the world, steel mills, foundries, furnace construction companies and material manufacturers rely on our expertise, which has been channelled into the design of our E426 and spurs us on in our continuous improvement of the unit. Estromat E426 is used around the clock, in all climate zones, and on all continents (with the exception of Antarctica)!

By default, the machine offers a storage silo with a useful capacity of 2.3m³ and a pump capacity of up to 80 l/min. But standard applications are the exception with our customers, which is why our E426 can do so much more!

Feed silos for very large volumes, interfaces for injection manipulators and robots (the machine can also still be operated manually), water heating or cooling, connection to process control benches, digital archiving of mixing and pumping parameters, combined systems for processing two or more different materials on one line – the variety of special designs already realised is almost endless.

But what sets our unit apart? The answer is: It is designed to be as simple as possible and as complicated as necessary!

Estromat E426 is designed to be your dependable, uncomplicated companion, a partner that solves problems without causing any!

Others tried to copy the Estromat E426, but the practical benefit often lies in the details. The original offers you numerous benefits, including a service life of the mixing and pumping components that is unique in the market and has never been achieved by the “copycats”! Because we understand why a component needs to look the way it does…

Putzknecht S30-TM 100

Compact, powerful mortar pump with built-on TM 100 pan mixer. The design of the mortar pump allows using another, separate pan mixer. The larger material hopper allows for quick and comfortable handling, even with large conveyor volumes.

The continuously adjustable drive allows the conveyor rate to be optimally adjusted to your needs.

Available with 5.5kW or 7.5kW drive. The machine can also be fitted with optional gunning equipment, a vibrating sieve and remote control.